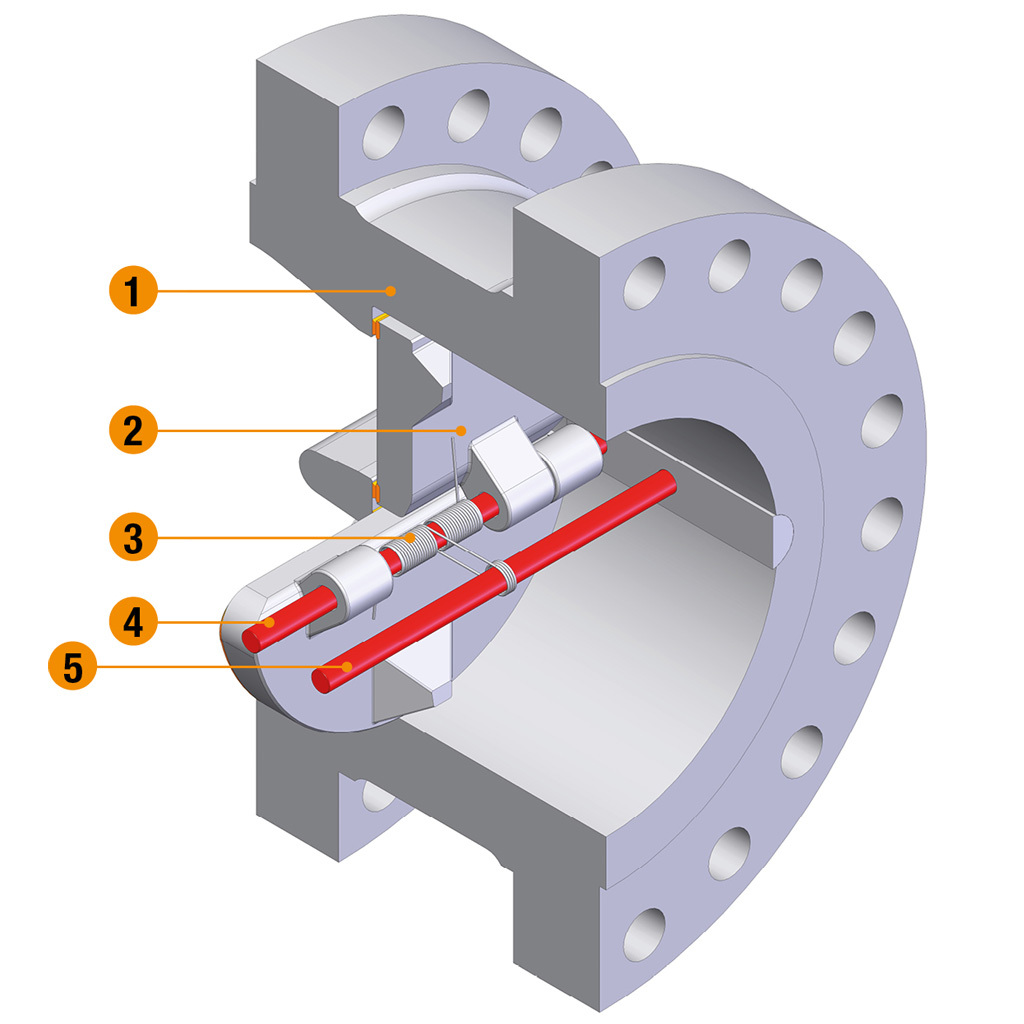

Double Flanged Check Valves

RETAINERLESS DESIGN ACCORDING TO API 594

Description

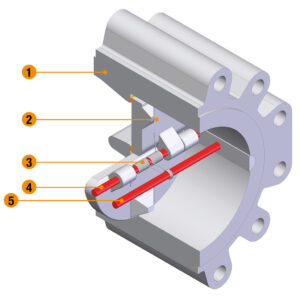

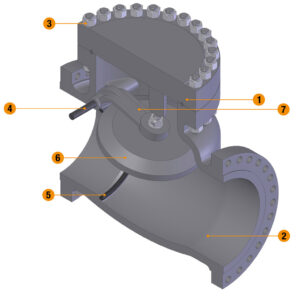

BODY

The body is realized in cast or forged steel, carefully designed in order to minimize the pressure drop. The basic dimensions, wall thickness, face to face and flanges, comply with the relevant API and ASME standards. Two guides are incorporated to ensure correct alignment of the hinge pin. The integral seat is part of trim Special attention is given to the seating surface which is ground and lapped, for a perfectly tight seal. The total absence of through-body drills (retainerless design) avoids any possible accidental leakage from the system.

DISC

The disc is in cast or forged steel. The attachment to the hinge pin allows the rotation and a small translation along the flow. The seating surface is ground and lapped. An integral over-travel stop for the discs is incorporated.

SPRING

Torsion spring, available in various material, according to the desired service.

HINGE PING

TThe hinge pin is part of the trim, in forged stainless steel and is machined from ground bar. The hinge pin is held in position in the body with two supports. The pin can be easily removed for valve maintenance. For correct valve functioning it shall be always installed in vertical position, when used in horizontal pipeline.

STOP PIN

The stop pin is part of the trim. It is machined from ground bar in forged stainless steel. It is held in position parallel to the hinge pin on the same support. It has a double function: it stops the disc and retains the spring’s trust. The pin can be easily removed for maintenance of the valve.